PROPOSAL FOR NEW WORLD STANDARD FOR TESTING SOLAR COOKERS.

Dr Ashok Kundapur, International Alternate Energy Trust, Kalashree, Udupi- 576 102, India, Email : arkundapur@yahoo.com

( This paper was read at International solar cooker Conference, at Granada,

Spain in June 2007. Co author of this paper is Dr

Sudhir C V

Engineering,

ABSTRACT

New protocol to test solar cooker is being proponed here. The earlier standard measures only the cooking capacity. There is a need to look into other important parameters of the cooker such as its stagnation capacity, cost per watts delivered, weight of the cooker, ease of handling and aesthetics. The proposal also aims at standardization of reporting the test results so that it can be easily understood by not so literates who wishes to use one.

Keywords: Solar Cooker Tests, Exergy, Efficiency, Standardization in Tests and Reporting.

1. INTRODUCTION

Solar Cookers have a long history dating back almost to 18th century when Nicholas-de-Saussure built first ever Solar Box Cooker. Today there are about 60 major designs and more than 100 of variations Kundapur(1) . However, the Solar cooking has not caught the imagination of the people, except in places where shortage of conventional fuel like fire wood and the like is acute, (Solar Cooking.org(2)).

Solar Cookers are meant to be used by, in most cases not so well educated persons, and hence testing of solar cookers and presentation of results have to be looked into more carefully.

The solar cookers have been subjected to several types of tests. Some of the tests conducted earlier has been summarized by Bowman(3).Later German Appropriate Technology Group conducted tests on many more popular solar cookers(4). Mullik et al., presented a set of tests procedures and equations to asses the Thermal performance of the Solar cookers especially the box type cookers(5). Many more solar cooker stalwarts proposed several variation of the tests. In the recent past, Petela(6) has taken into account exergy aspects. However, it was in the year 2000 that Funk et.al.(7) found a need to evolve a International Standard for Testing Solar cookers. The recommendations were later adopted by United States Agricultural Engineers as ASAE S580.

Nandwani(8) and also Mukaro(9) have conducted tests on solar cookers and have reported the thermal performance in terms of percentage efficiency. While ElSebaii et al,(10) Florida Solar Energy Center FSEC(11) and Steven Jones et al.(12) have conducted tests as per ASAE S580 for Box type or Panel type of cookers. But it is very difficult to have a comparative data as many other popular type of cookers, like Parabolic, have not been subjected to standard tests and hence there is an urgent need to evolve a comprehensive test.

It is interesting to note that while earlier tests (2 & 3) did consider many aspects of Solar cookers such as handling, time of cooking and the like, along with thermal performance, recent tests concentrated only on Thermal performance. Besides, the figures obtained after the tests were not easily comprehendible by the common man/woman. The present proposal recommends a set of tests which in the words of Shawn(13) “proposes presenting thermal, qualitative and ergonomic data into an understandable, reproducible and rigorous testing method”.

Before we go further we urge that the recommendations presented here should be taken as general guidelines for more down to earth tests, than the final verdict.

2. BACKGROUND

Without going into the details of pros and cons of equations used by other researches in the past, the authors like to start off from the present International Standard Test recommended by Funk et.al(6) which is now the only standard universal test. The test specifies many important parameters and stipulations for testing. Most important being amount of water per square meter area of Cooker and to measure temperature of water only up to 900C, to avoid vagaries of water near boiling point. The following equation (1) is used to arrive at Cooking Capacity or Power of the Cooker.

![]() (1)

(1)

Where P is the Cooking power, Tw2 is the final, and Tw1 is the initial water temperature, mw is the mass of water, Cpw is the specific heat capacity of water, and t is 10 min ( 600 sec ), thus P represents values per second.

Finally P is normalized ( Ps ) to a figure of 700 W/m2 through the following equation (Equation 2), where Iaw is the average Insolation

(2)

(2)

While ASAE S508 provides a simple test to establish a universal figure of merit, the figure as such would not make much sense to general user.

European Committee on Solar Cooking Research (ECSCR) in 1992 recommended more exhaustive thermal Testing, and also considered certain other aspects of Cookers such as safety factors, ease of access to cooking pot, durability and the like. The thermal testing regime specified by them under ‘Basic Test’ included many stipulations, some of the important ones are listed bellow,

· Water at 40°C is placed in a pre-heated cooker for two hours around solar noon ( ie., 11.00 to 13.00 hrs)and maximum temperature is recorded.

· The cooker is turned towards the sun and left. The time taken for the water inside to reach 80°C is recorded

· Oil, at 40°C, is heated from 11:00-13:00 and the maximum temperature is recorded

· Hot oil from the previous test is left to cool in the cooker out of the sun. The time taken for the oil to cool to 100°C is recorded.

· Repeat the test conducted as per first point, in non heated cooker.

· The pot lid(s) is removed and the time recorded for the water from the previous test to cool to 80°C with occasional stirring

· Water at 40°C is heated with the sun at a low angle. Temperature is recorded as a function of time. This measure is intended to test cooker performance in morning and evening conditions.

These variations in the recording of temperature has not been reflected in the calculations. But as far as the reporting of test results are concerned there are no uniform standards and the authors suggest the following

Ø Far as possible reporting the thermal performance results in percentage, and all temperature recording to be reported in Centigrade or Fahrenheit.

Ø Standardization of nomenclature of symbols used in the equations,especially,for Solar Cooking Tests

.

.

3 PROPOSAL OF NEW STANDARDS

In the light of the discussions made above, the authors takes the liberty of presenting the following suggestions, for testing and reporting of results on solar cookers.

1 Thermal performance test :(Reporting with the help of color charts as in FSEC), and always expressed in Percentage, Temperatures recorded to be displayed in Centigrade as well as Fahrenheit. (Temperature could be expressed in Kelvin in case of a Technical Report )

2 Stagnation temperature: (The results helps to understand the thermal capacity and quality of the cooker )

3 Heat loss test :(Results of first three tests should be expressed in percentage, because it is easy to comprehend by any user, and the expression is rather universal)

4 Standard Cooking Time or Max load test.

5 Tests for Heat storing components : ( This is going to be an important factor in the future, )

6 Ray Trace Diagrams: should be made mandatory in all test reports. This would prevent any tall claims.

7 Ergonomic considerations: and ease of use

8 Cost / watts :( This factor would influence the user to a great extent. Considering the number of poor in the world, the author feels that do-it-yourself designs should be paid more attention by Scientist)

9 An active user should form part of the test and his/her observations, especially on last two points should be included in test report.

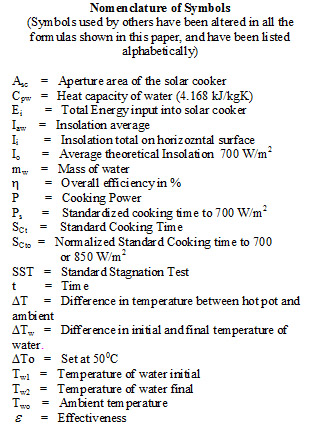

As regards the nomenclature of Symbols following is the list of some of the most frequently used in solar cooker Testing. All of them are not new, but in future they could be adopted by all Solar Cooker scientists.(The Exergy factor r is not shown in the chart)

.

.

.

Thermal Performance Test

Thermal Performance Test

Stipulations made in ASAE S580 for conducting test appear to be ideal for this type of test. However care should be taken to use right type of vessels for testing for a particular type of Cooker. Wherever possible, best quality solar guard (Greenhouse enclosure) should be used, even in Concentrating type of cookers.

Quantity of water taken for testing has a bearing on aperture size and performance of the Cooker. In case of Box type - Aperture of Cooker is sum of area of Reflector and ‘glazed window’. In case of panel cooker, aperture is to be taken as area of rectangle formed by the folded assembly rather than the total area of reflecting area when it is unfolded. The suggested quantity use of 7kg of water/m2 of Solar Cooker aperture appears to ideal.

The final figure obtained through equation 2 gives standardized ‘cooking power’ per second,(Po). But it would be difficult to express the result on a percentage basis. To do this some more data, like total amount of ‘heat’ reaching the cooker is required. This can be arrived at through equation 3

![]() (3)

(3)

Where E1 is the energy input of the Cooker in Watts

From this figure, and obtaining all the values for calculating Power as shown in equation 4, the efficiency, η can be calculated using the equation 4

(4)

(4)

The Test results can now be expressed in percentage.

Exergy is an important parameter, hence the authors suggest incorporation of this parameter as well. In which case the calculations is to be performed through follow equation(5)

(5)

(5)

Where r is Exergy factor indicating loss of energy from the device. This factor would in turn help during redesigning process to hence in making the device more efficient.

Simplifying this further one arrives at the following (6)

![]() (6)

(6)

where,

I aw = Solar insolation falling on the cooker aperture area.

![]() = r Iaw

= r Iaw

(7)

(7)

Effectivness ![]() of the cooker shall be evalauted as in equation 7., Thus

effectiveness in terms of efficiency in percent illustrates as to effectiveness

of Solar Cooker in converting the Insolation falling on it to heat energy.

of the cooker shall be evalauted as in equation 7., Thus

effectiveness in terms of efficiency in percent illustrates as to effectiveness

of Solar Cooker in converting the Insolation falling on it to heat energy.

Lot has been said about effect of wind speed, ambient temperature on performance of solar cooker. Some of the tests direct to discard data obtained if the Insolation or wind speed is higher than that stipulated. To ensure reproducible result, the authors recommends that these thermal tests be performed in laboratories with suitable simulators, rather than in open.

3.2 Stagnation Temperature ( Theoretical, Practical)

Stagnation Temperature test is an important parameter, because it depicts the ability of a cooker to develop maximum temperature, which in turn reflects on the quality of design and performance. This would enable the designer/ manufacturer to use the right material to increase the ‘ability’ of the cooker to develop maximum temperature.

Many authors have recommend use of empty vessel to conduct the test, or just the cooker without any vessels. Final verdict on this aspect is left to the international experts.

Equation 8 enables calculation of Standardizes Stagnation temperature

![]() (8)

(8)

Some researchers like Shaw, have suggested the Insolation value at 850W/m2 as in above equation for standardizing the values, but as suggested in ASAE S580, 700 W/m2 can also be used. Authors feel that 700W/m2 is ideal, if at all this step is found very essential.

If the insulation of a box cookers is not of good quality, or if the green house enclosure of the panel cooker is too large in comparison to vessel/plate or if the reflector in a Parabolic cooker is not of the right quality, then it would get reflected in this test. In other words this test would ascertain the quality of manufacture, in terms of design and insulation.

3.3 Heat Loss Test.

This test reflects and substantiates the finding of test 2. A known quantity of hot water at 800C is kept in the cooker (or Green house enclosure as the case may be) and loss of temperature is recorded till the water reaches ambient/room temperature. The result expressed in hours is a good comparative parameter.

3.4 Standard Cooking Time or Max load test.

Max cooking load per batch should be specified by the designer or manufacturer of the cooker. When this is done it would be easier for the Tester to load the unit with specified quantity of water test the cooker. Some scientist have suggested loading only water. But the Authors prefers use of actual material, and recording the temperature as well as actual cooking time, and even ascertain taste of food. Rice cooked in substandard cooker would be rather bland compared to that cooked in a good quality cooker.

![]() (9)

(9)

In the Equation 6, SCt is the standard cooking time, and ηo is the Optical heat transfer coefficient – a proportionality constant that combines several factors relevant to transfer of energy through optical materials of the cooker, like glass and material of the cooking vessel. Naturally this factor would be of importance to Box type cooker, and to a certain extent to Panel type of cookers as well. While other symbols have been defined and used already,

3.5 Test for Heat storing components

Heat storing component/material are going to be a part of the solar cooker of the future. So it then becomes essential for the scientists to suggest suitable materials and their heat storing capacities. Götz, of ULOG, Switzerland, has used molten Tin for storing heat in Scheffler’s cooker. The Tin melts during the day and stores heat for the night. Schwarzer et al have used pebbles. Others have suggested oil. Variety of material have been used, but which is better, if not best, has to be ascertained.. While doing so, the storing capacity of the enclosure/cooker has also to be estimated. Time factor as suggested in the test 3 can be used here and when the data obtained is tabulated, along with the cost per unit ( like kg. ) one gets an idea as to the best available heat storing material. Heat transfer coefficients can also be plotted along.

Most of the data obtained through these tests can be plotted, when it is done with suitable colors, one could get a clear picture as to the efficiency of different types of cookers.

3.6 Ray trace diagrams.

Ray trace diagrams are not new in Optical Instruments, but rarely a mentions has been made with reference to solar cookers. Such diagrams become essential for panel type and parabolic cookers of different designs. They would be more attractive and illustrative for the user. Such diagrams could be made very effective if produced in Flash program, as is done by Pardeshi of India(13). FSEC has also attempted this technique and have tried to improve Panel cooker.

3.7 Ergonomics and ease of use

This is a users prerogative and apart from the scientist or designer actively working on or designing the cooker, the user too should be actively consulted in this regard. For example, scientists who have conducted comparative test have expressed such difficulties in using a Chinese Parabola and regular Parabola, but how does a common house holder feel about it ? Chinese design was specially designed to off set some of the difficulties in regular Parabolic Cooker.

3.8 Cost/Watts

Before such a calculation is attempted it would be essential to calculate efficiency of a cooker and then estimate cost per watts delivered by the cooker in standard currency like Euro or US $.

3.9 User opinion

Many of the tests recommended, hardly give any scope for the user to record his/her opinion. A knowledgeable user has to be given a chance to express his opinion and suggest changes in the design. When this is done the development of cooker would be faster.

4. CONCLUSION

Summing up, there is an urgent need to evolve a set of universal standard tests to evaluate Solar Cookers and their components, and presentation of results in a manner understandable even to the comman user.

5. REFERENCES

(1) Kundapur Ashok., Review of Solar Cooker Designs, TIDE, 8(1) 1-37, 1988,(also http://solcooker.tripod.com)

(2) Solar Cooker International., http://www.solarcooking.org

(3) Bowman T.E., Blatt J H., Solar Cookers, history, design, fabrication, test and evaluation , Florida Institues of Technology, 1978

(4) GATE., Comparision between different systems of Solar cookers, German Appropriate Technology Exchange, 1979.

(5) Mullik et.al., Termal test procedures for box type Solar Cooker, Solar Energy Vol 39(4) 353-360, 1987

(6) Patela Richard., Exergy análisis of Solar cylindrical parabolic cooker, Solar Energy 79,221-223, 2005

(7) Funk Paul., Evaluating the internacional Standard procedure for testing solar cookers and reporting performance, Solar Energy, 68(1) 1-7, 2000

(8) Nandwani SS., et.al., Experimental study of multipurpose solar hot box at Freiburg, Germany, Renewable Energy 4, 1-20, 1997

(9) Mukaro R., Tinarwo D., Performance evaluation of a hot box reflector solar cooker using a microcontroller based measurment system, ( accepted for publication )

(10) El Sebaii A A., Ibrahim A., Experimental testing of Box type solar cooker using the Standard procedure of cooking power, Renewable Energy, 30, 1861-1871, 2005.

(11) FSEC, Solar oven testing and development Project, Florida Solar Eergy Center, http://www.fesc.ucf.edu/solar/

(12) McMillan C., Jones S., Tests of the the Solar Funnel and Bowl Cookers in 2001 (http://www.solarcooking.org/funneltest01.htm)

(13) Shaw Shawn., Development of a comparative framework for evaluatimg the performance of Solar Cooking devices, Thesis submitted at Renselaer Polytechnic Institute, USA, 2002

(http://www.solarcooker.org/Evaluating-Solar-Cookers.doc)